Quality and Reliability

Zhanxin adheres to stringent standards, including GB/T 19001-2016 Quality Management System, GB/T 24001-2016 Environmental Management System, and GB/T 45001-2020 Occupational Health and Safety Management System. Through robust system operations, strict adherence to procedural guidelines, and comprehensive work instructions, we ensure meticulous control over quality, environmental factors, and safety hazards.

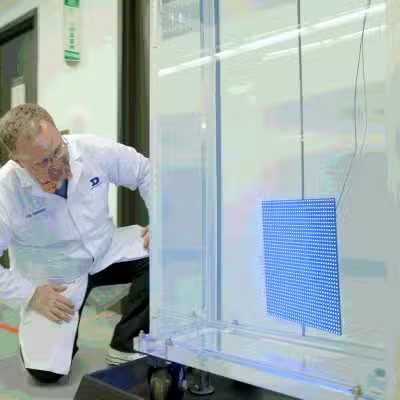

Zhanxin Laboratory

Located at our headquarters in Longhua District, Shenzhen, China, Zhanxin Technology operates a state-of-the-art laboratory as a leading manufacturer of digital displays. Here, we conduct rigorous testing on LED display components to ensure superior performance and durability.

Our full-suite services include image quality assessment, performance evaluation, and stress testing to identify potential weaknesses. Our engineers leverage test data to enhance and innovate our indoor and outdoor products, guaranteeing unmatched integrity, quality, and reliability for years of dependable performance.

Integrity Testing

We evaluate product performance under diverse environmental conditions, focusing on optical performance, power consumption, efficiency, and more.

Light and Image Quality

In our image quality lab, we measure module light output and color characteristics to gather performance data. This enables us to assess display performance across various viewing angles and under challenging conditions like direct sunlight or overhead lighting. We also provide 3D photometry files for lighting designers requiring detailed specifications.

Color and Contrast

Using an integrating sphere, we measure the luminous flux and color properties of individual LED samples to verify supplier specifications. In controlled environments with consistent lighting, we assess the impact of ambient light on contrast performance, expressed as the Ambient Contrast Ratio (ACR), a key indicator of real-world display performance.

Compatibility and Thermal Performance

Our electrical radiation absorption chamber ensures compliance with federal and international electromagnetic noise regulations, preventing interference with internet, radio, or cellular signals. Large-scale environmental test chambers simulate full-sunlight conditions to evaluate the thermal performance of heating and cooling systems, ensuring reliable operation across diverse environments.

Reliability Testing

Our rigorous testing ensures sustained image quality over time, giving customers confidence in the long-term performance of our displays.

Climate and UV Resistance

To prevent degradation of materials like plastics, silicone, epoxy, coatings, and LEDs, we conduct UV aging tests under ultraviolet light and condensation conditions. Temperature and humidity chambers simulate extreme environments, testing component resilience to moisture, corrosion, hydrolysis, and electrical changes. These tests span temperatures from -40°C to 100°C (-40°F to 212°F) and humidity levels from 10% to 98%, assessing material expansion and solder joint strength.

Waterproof Performance

Our modules are designed to withstand heavy rain and humid conditions. We perform comprehensive waterproof testing, including high-pressure 360° water jet sprays, internal waterproofing inspections, and submersion in 1-meter-deep water for 30 minutes to simulate extreme conditions.

Global Leader in LED Display Solutions

Driven by innovation, we uphold the belief that technology creates value—crafting premium LED Displays to deliver exceptional visual experiences and greater added value for our customers.